MEMOPUR®

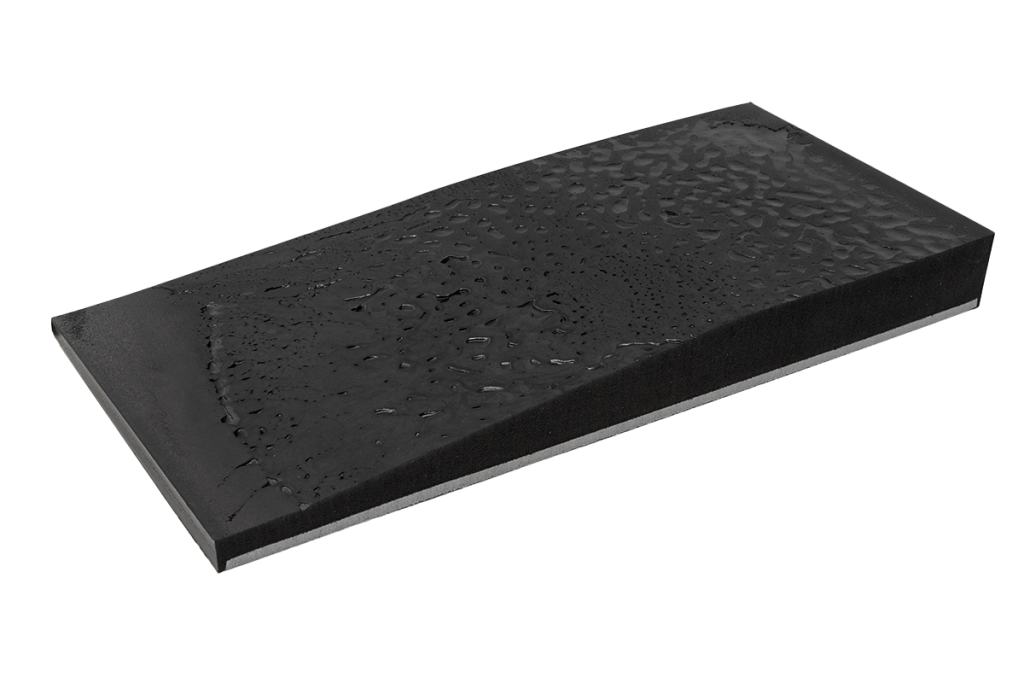

The insole blank made of very finely structured, open-cell polyurethane foam for use in the footbed and optimum pressure distribution.

MEMOGEL®

The Memopur® base element offers excellent damping properties. The gel elements are precisely adapted to the respective load, act hydrostatically and thus cause an enormous pressure distribution.

MEMOPUR® KIDS AND SPANNTEC® KIDS

The insole blanks can be individually adapted to the foot due to their thermoplastic deformability property and the included supination wedge.

We use PU foam specially developed for SPANNRIT to manufacture our MEMOPUR® insole blanks in a single computer-aided casting. We have over 120 models in stock for you. You decide how you want your insole blank to be. No more time-consuming grinding or complicated gluing. Minimal adjustments are sufficient. High quality at attractive prices can be that simple.

1. upper material: SILVERLINE is the innovative upper material with a ten percent silver content. Has an antibacterial effect and is extremely absorbent.

2. protective layer: Protects the gel elements.

3. gel elements: Are precisely adapted to the respective load. Act hydrostatically and thus cause enormous pressure distribution.

4. MEMOPUR® base element: Offers excellent damping properties and has a high restoring force.

5. core base: Extremely resistant stiffening layer. Gently supports the foot. Musculature can work actively despite correction.

6. heel absorber: Particularly resilient heel absorber with damping properties.

The K22 is the first extra light carbon blank from SPANNRIT.

The heel and the base 5 are particularly flexible. The heel thickness is 0.1mm. The plastic is made of a very break-resistant and thermoplastic material that is very easy to form. After grinding, the material can be restored to its translucent appearance by tinting. The K22 can be used as an everyday insole as well as a sports insole.

It is a unique combination of appearance, function and workability – at an unbeatable price.

SPANNTEC® is a concept for manufacturing high-quality plastic blanks by injection molding. It is a combination of soft, flexible plastic at the heel, edges and forefoot and a firm, resilient comfort core in the longitudinal arch and rearfoot area. In this way, synthetic insoles are created to meet the highest demands. No pressure points can develop on the soft edges. The heel is so thin and flexible that the foot is not levered out of the shoe. The top side is provided with an adhesive aid so that it has excellent adhesive properties.

All transitions are smooth due to the special production process – the customer does not feel any edges.

Super thin. Although extremely stable. With a hard core. And soft edges. An inlay blank cannot be better prepared.

We manufacture our SPANNTEC inlay blanks from plastic or cork developed in-house. You determine not only the material, shape and color, but also the type and position of the pad. The cover material. The bonding. Even the thickness of the heel pad. Completely according to your needs. And new for every order, if you like. That’s how customer-friendly collaboration can be.

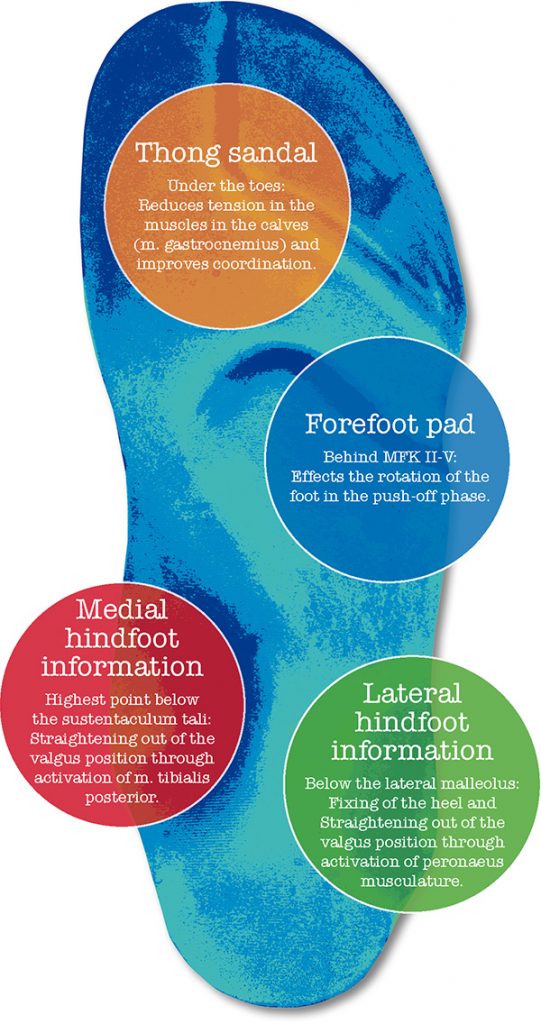

memopur.senso is the new insole for sensorimotor care. It provides the perfect basis for low-cost manufacturing and production.

1. memopur.senso enables effective restoration according to the most modern principles in insole construction. A total of seven different basic models can be created from three blank types. This creates a professional range of restorations for every workshop with little effort.

2. memopur.senso combines excellent material properties such as dimensional stability and cushioning with very good processing possibilities, e.g. grinding or bonding.

3. direct contact with SPANNRIT with insoles “Made in Germany” means that you do not need to keep stock and can guarantee efficient and customer-oriented insole production with just a few models. Delivery times are thus within a manageable range.

4. memopur.senso supports your work with marketing and information material around the insole supply.

mempur.senso creates the freedom you need for your insole construction. Because with memopur.senso blanks, you will meet all the requirements for a sensorimotor fitting.

It is crucial that you always maintain an overview. This is because different supply steps can be defined from one blank. A blank offers you up to three variants so that you are as flexible as the customer requires.

Step 1: Analysis and findings

Load matrix by blueprint or foot scan, optical gait analysis, palpation of the feet.

Step 2: Evaluation of findings and selection of raw material

Preparation of the work sheet and selection of the blank and suitable materials for finishing.

Step 3: Customization of the individual insole

Planning of the insole relief according to indication. Machining and finishing by your specialist workshop.

Step 4: Sale and follow-up care of the customer

Delivery of the insole to the customer. Fitting to the shoes and first test run. Check after the acclimatization period (approx. 14 days) and after four to six months.

Discover our variety of interlinings from the MEMOPUR®, MEMOGEL® and the SPANNTEC® program as well as our selection of stock items, cash register models, children’s blanks, foam blanks, plastic blanks, cork blanks, components, ceiling materials and modular systems. Furthermore, you will find information about inserts with your imprint in our catalog.

Our latest insole innovations. Insoles technology for special applications, such as ballerias, pumps and many more.

Learn interesting details about the novel memopur.senso insole. This sensomotoric insole is an insole for a very special organ.

Browse through the flyer on the MEMOGEL® insole system and learn about its special features, such as the HydroEnergy Effect.

The K22 is the extra light blank made of high-tech material from SPANNRIT. Discover the flyer to the very break-resistant and thermoplastic very easily deformable insert.

A simple step-by-step guide explains how to attach the additional rigidus reinforcement.

A simple step-by-step guide explains the gluing process with an individual pad.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Bunny Stream. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Wistia. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information