For over 50 years, we have relied on a healthy mix of tradition and innovation.

Over the past decades, we have built up unique expertise through targeted expansion in the shoe component market, which is constantly incorporated into the development of our products: The portfolio here ranges from wooden heels to clamping sleeves and the production of outsoles to industrial injection molding. In doing so, our entire commitment is to individual and high-quality solutions that convey a correspondingly valuable price-performance ratio.

In a professionally intensive exchange with our customers, we use their extensive experience in a craft rich in tradition and integrate it into the development of state-of-the-art technical solutions. Thus – also based on scientific findings – the entire product range of the SPANNRIT insole was developed.

If something needs to be done more efficiently, it’s best to bring in someone from outside the industry. Who questions the processes. And logically rethinks.

This is exactly how Roland Katzer did it at SPANNRIT. As a career changer, he took over the family business in the third generation. “There’s got to be a better way to do this in terms of quality,” he thought to himself as he glued together the insole components for his customers by hand back then. The trigger was his allergy to oil and solvents. So the technology fan fiddled around until, together with his mechanical engineer, he had optimized the production processes down to the smallest detail. Eight patents resulted from this. Even today, they are used in almost all products.

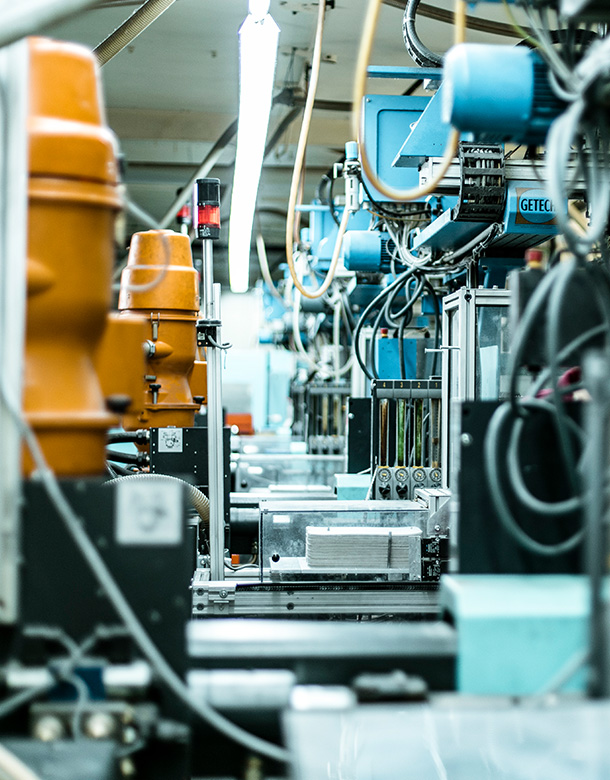

Today 18 computer-aided machines take over the part of the work that even the most skilled hand would not be able to do with such precision. All inserts are made of continuous materials without transitions or edges. The blanks are then individualized by hand. Every single one for every single order. Computer-aided only where it makes sense. Everything else handmade. Always with the best end result in mind. For you. And thus also for your customers.

2019 – Structure photovoltaic system: Predominantly used in self-consumption. Paternoster extension: expansion of the mold storage by 4 times.

2018 – Merger of the SPANNTEC® and MEMOPUR® ranges to form the MEMOPUR® Duo range.

2016 – Extension of the production hall.

2015 – Change of name to SPANNRIT GmbH. Customized insole design using underwire technology.

2014 – 3D lasts and insoles.

2013 – Introduction of microwaveable insoles.

2012 – Introduction of the MEMOPUR® Senso program.

2011 – Managing Director Agilhart Katzer passes away at the age of 70.

2010 – Capacity increase for MEMOPUR® by one third. Addition of warehouse and shipping hall.

2008 – Expansion of the company premises (warehouse 2) with approx. 70 employee parking spaces.

2007 – New construction of a modern production hall on 700 sqm.

2006 – New purchase of the most modern PU plant for insole production.

2005 – Expansion of the SPANNTEC® collection.

2004 – Introduction of the SPANNTEC® and MEMOPUR® range.

2003 – New development of the orthopedic bearing program.

2002 – Completion of the 300 sqm extension.

2001 – Further doubling in size of the orthopedics department. Start of the extension of the administration.

2000 – The size of the orthopedics department is doubled.

1999 – Further expansion of the orthopedics program. Completion of the building extensions.

1998 – Expansion of our orthopedics program. Start of a 1,200 sqm building expansion.

1997 – Market launch of our patented air chamber system for footbeds.

1996 – Change of name to SPANNRIT Schuhkomponenten GmbH.

1995 – Market launch of our own development: Sunbed-Comfort cork insoles.

1994 – Entry into the production of blanks for orthopedic shoe technology.

1992 – Building extension by 700 sqm on the ground and second floor.

1989 – Production expansion to 10,000 pairs of floor parts per day for the shoe industry.

1988 – Extension of the production hall on the first floor.

1986 – Addition of another floor to the factory building as a storage area. Second floor

1985 – Expansion of sole production. Additional injection molding machines and 10-station rotary machines are purchased.

1984 – Change of name to SPANNRIT Plastics GmbH. Entry of the third generation.

1976 – The first 10-station rotary table injection molding machine for EVA foam wedges starts up.

1975 – Start of shoe sole production with new injection molding machines.

1969 – Existing production building is extended by adding the second floor.

1966 – Start of production of new development of penny stains made of injectable polyurethane (TPU).

1965 – Acquisition of four additional injection molding machines for the production of plastic heels.

1963 – Expansion of the production building by 50%.

1962 – Cessation of wood sales production. Expansion of the “SPANNRIT” range and worldwide export.

1961 – Establishment of the company’s own automatic turning shop with 13 machines for the production of 100,000 pairs of brass penny stamps per day.

1960 – The era of plastics processing begins with the purchase of the first injection molding machine for the production of plastic plug-in patches.

1959 – Trademark SPANNRIT is granted and incorporated into the company logo. Change of name to SPANNRIT KG Franz Katzer.

1958 – Relocation to new building in Kleinostheim. First own patent and utility model application.

1955 – Entry of the 2nd generation (Agilhart Katzer).

1952 – Change of name in Aschaffenburg: “Holzabsatzfabrik Franz Katzer”.

1950 – Change of name to freight forwarder: Spessart-Transport-Aschaffenburg Franz Katzer.

1946 – Foundation of the transport business by Franz Katzer in Aschaffenburg.

We are committed to protecting the environment and sustainability by using renewable energy sources and minimizing our waste production. We also consider the impact of our supply chain and seek to strengthen our partnerships with companies that share our goals.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Bunny Stream. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Wistia. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information